Polyetherimide (PEI) Resin

What is PEI Resin?

Polyetherimide (PEI) Resin is a blend of polyphenylene ether (PPE) and polystyrene. The PPX blends are unique in that unlike other resin systems, the two polymers are compatible in all proportions. Because of this unique characteristic, polyphenylene products can be made with heat distortions that range from a low of 170 F (styrene) to a high of over 350 F (PPE). With different ratios of the two resins and the incorporation of additive packages for impact strength (non-brominated FR, reinforcements, etc.) a family of products can be made featuring UL-VO to UL HB and UL 5V, high stiffness, and high impact and processability. Both resins are inherently hydrolytically stable that makes the blends suitable over a wide temperature and humidity range.

The polyphenylene products exhibit a unique feature of retention of tensile and flexural strength and low creep even at elevated temperatures.

Impact strength of the polyphenylene family of products is typically unaffected by factors such as humidity and only slightly by temperature and wall thickness. A key advantage of PPX resins is that they maintain their impact strength, even at sub-zero temperatures.

Additives, Modifiers, and Reinforcing Agents:

- Additives – UV stability, easy release (mold releases), colorants, and other stability additives

- Modifiers – Flame retardants, impact modifiers, flow enhancers

- Reinforcing Agents – Glass fibers, mineral fillers

PRL Alternative Material Solutions to

Example: If you’re looking for Sabic Ultem alternatives: find the product in the relevant row and look to the leftmost row to find our alternative.

PRL Grades

- PRL PEI-GP1

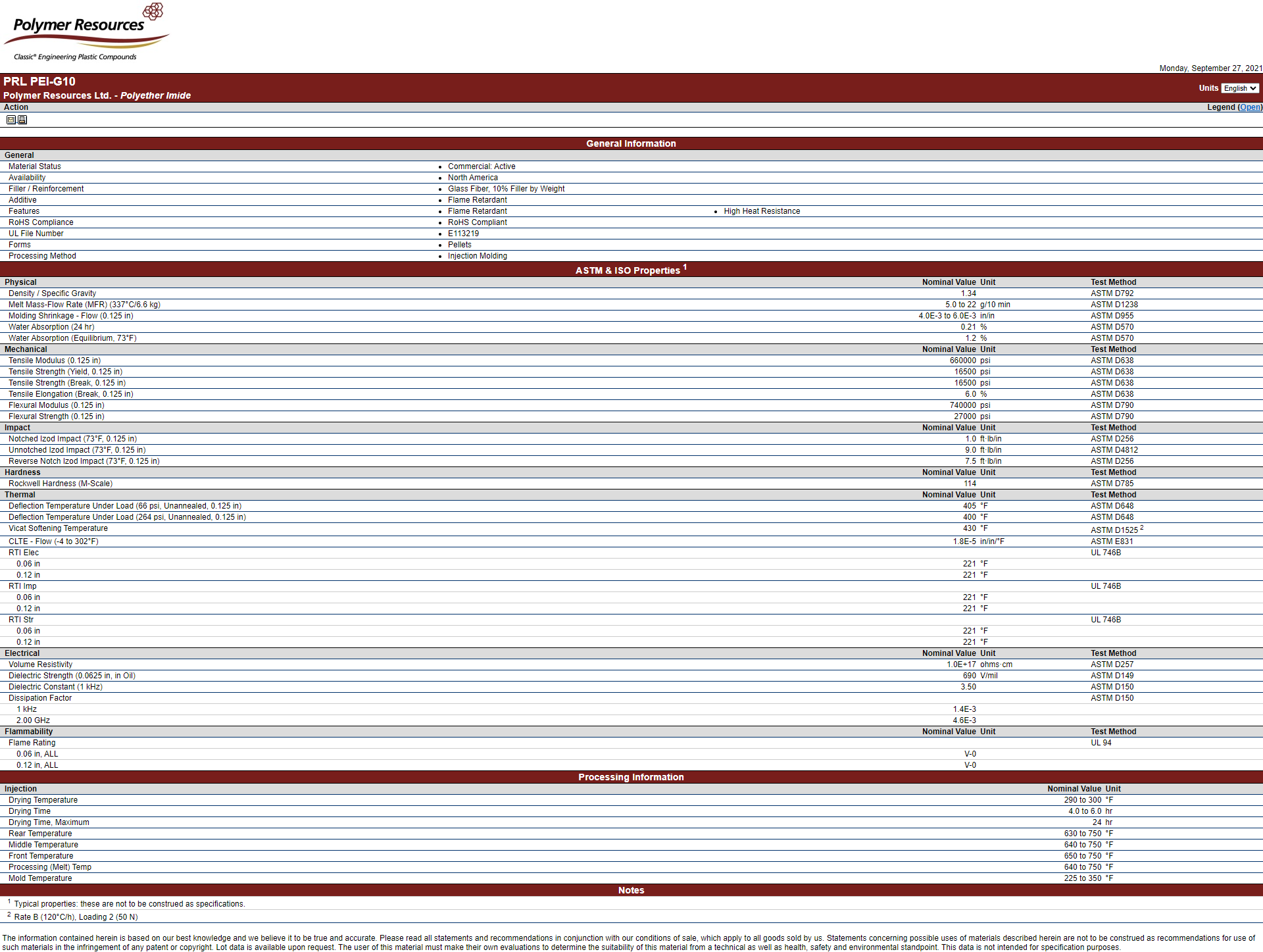

- PRL PEI-G10

- PRL PEI-G20

- PRL PEI-G30

- PRL PEI-G40

Sabic Ultem®

- 1000,1010

- 2100, 2110

- 2200, 2210

- 2300, 2310

- 2400, 2410

PRODUCT Q&As

Q. What is the development history of PEI?

Q. What are the advantages and disadvantages of PEI?

Q. What applications is PEI used for?

Q. Does clear polycarbonate turn yellow?

Q. Does polycarbonate absorb water?

Our Mission

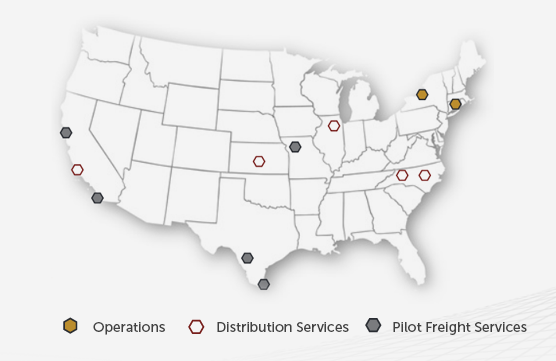

My mission at Polymer Resources has not changed since I founded this company more than four decades ago. It includes continuing our tradition of financial stability, sustainable growth and visionary leadership that compounds success for customers, suppliers and employees. It also means proudly manufacturing our products in America, and making them available to the global marketplace.

Les Klein, Chief Executive Officer, Polymer Resources, Ltd.

Print

Print Download

Download Email

Email