Polymer Resins and Thermoplastic Compounds for Key Markets

Electrical

Polymer Resources understands the needs and demands required to be competitive and continues to be a leader in supplying NEMA and UL approved engineered thermoplastics in the marketplace.

Inquire About an Resin

Would you rather speak with a human?

Call (800) 243-5176

Non-Invasive Medical Devices

The medical device and equipment industry requires stringent parameters when dealing with medical-grade resins. Our focus on out-of-body devices requires strict tolerance and certifications.

Consumer Goods

Polymer Resources is a supplier to many markets within the consumer goods segment. Our global sourcing capabilities are unmatched and in house technologies comparable to the majors.

Transportation

The transportation and automotive industry today is very competitive. Therefore, Polymer Resources provides the highest quality material and service to meet OEM specifications.

Building & Construction

We understand what it takes to be #1 in the industry; let us help you achieve your goal of leading your business segment.

Who It’s For

Procurement

Our mission is to create a long-standing partnership with the procurement team, ensuring each organization’s needs are met. We pride ourselves on personalized and customized service solutions.

Engineering

We understand engineering as well as the significance of technology and innovation within engineering. Therefore, we will work hand in hand with the engineering team(s) of organizations to develop the most effective and efficient, performance-based material supply programs. What’s more, with our many regulatory approvals, it’s often effortless to introduce Polymer Resources to new programs.

Production

Qualifying and purchasing material is one piece of the equation. We have a technical team with the ability to travel 24/7 to ensure material processing on the floor is seamless.

Sales

Partnering with sales teams enables us to be on the leading edge of new product designs and at the forefront of industry boundaries providing speed to your marketplace.

Get Polymer Resins with Four Key Benefits

Our business and staff deliver flexible and attentive service tailored to the needs of individual customers.

Polymer Resources applies exacting standards to ensure the highest quality and consistency of our products and services.

We understand that speed is often as critical as quality, so we have organized our business to help you get to market faster. We offer express services for color matching and manufacturing to facilitate speed to market, demand fluctuations, and last-minute changes to forecasted business.

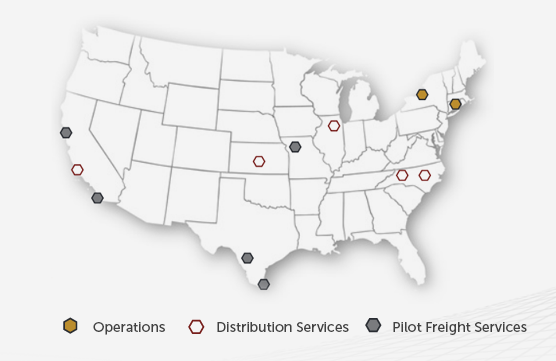

You can rely on Polymer Resources for consistent products that are available whenever and wherever you need them. Keys to our stability are:

Compounding Success for Over 50 Years

American Made for a Global Marketplace

Our Mission

Les Klein, Chief Executive Officer, Polymer Resources, Ltd.