PC/ASA Resin

What is PC/ASA Resin Material Blend?

ASA and PC/ASA The acrylic-styrene-acrylonitrile terpolymer (ASA) is an amorphous thermoplastic material that offers good resistance to both UV and moisture. PC/ASA is an amorphous thermoplastic alloy of polycarbonate (PC) and ASA that provides enhanced heat resistance and enhances mechanical properties.

Additives, Modifiers, and Reinforcing Agents:

- Additives – UV stability, easy release (mold releases), colorants, and other stability additives

- Modifiers – Flame retardants, impact modifiers, flow enhancers

- Reinforcing Agents – Glass fibers, mineral fillers

How ASA Material is manufactured?

ASA Applications

- Automotive

- Outdoor Products

- Building and Construction

- Sports equipment

- Exterior signage

- Consumer Products

- Electronics

- Medical products

Methods of Working with ASA Resin

- Molding

- Welding

Benefits of ASA Materials

- Good UV resistance

- Nice glossy surface,

- Tough and strong

- Chemically resistant

- Lower color fade

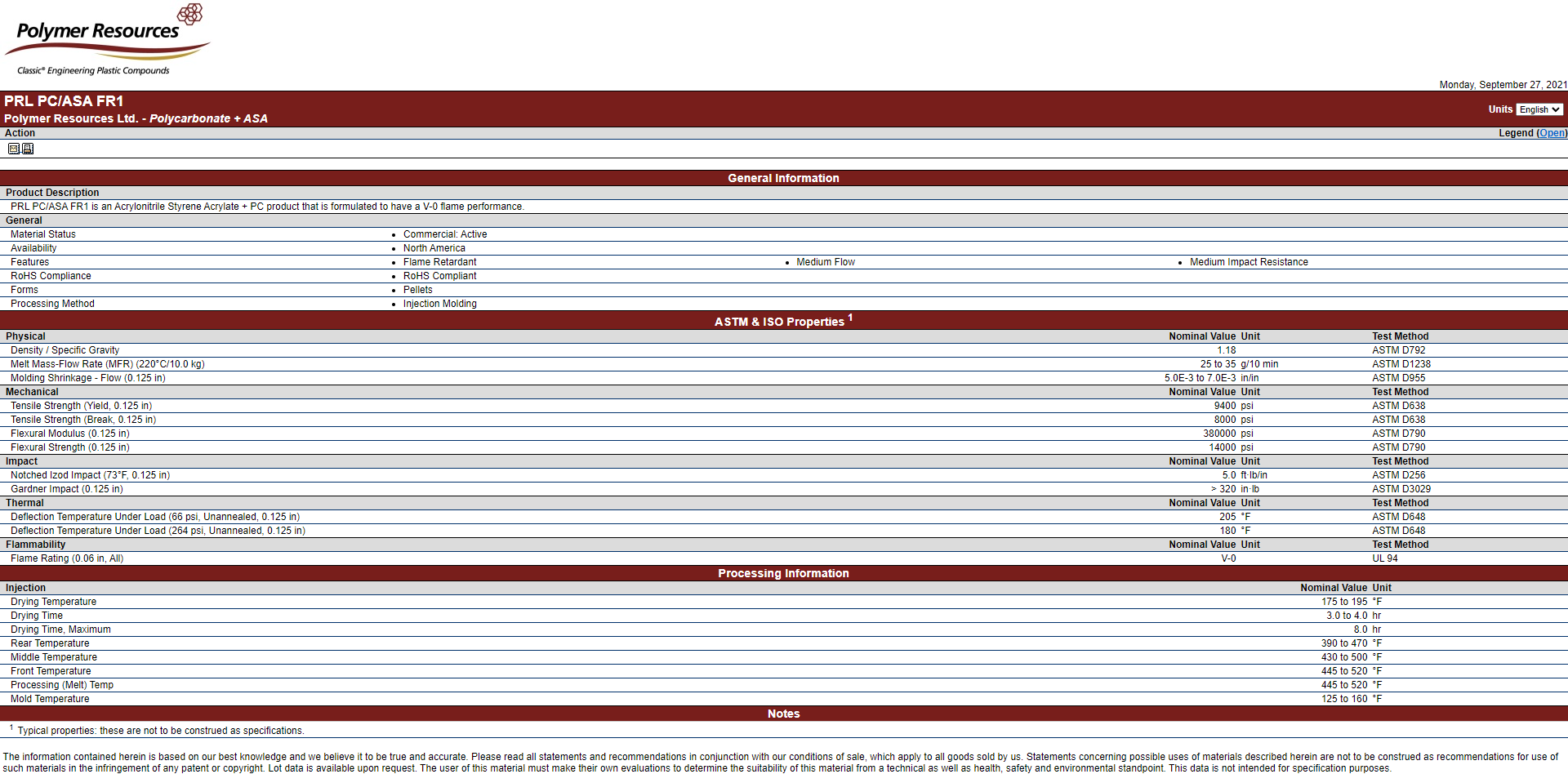

PRL Alternative Material Solutions to

Example: If you’re looking for Covestro Bayblend alternatives or Ineos alternatives: find the product in the relevant row and look to the leftmost row to find our alternative.

PRL Grades

- PRL PC/ASA GP1

- PRL PC/ASA GP2

- PRL PC/ASA GP3

- PRL PC/ASA FR1

Covestro Bayblend®

- Bayblend® W85 HI

- Bayblend® W85; W90 XG

INEOS

- Luran® 757

- Luran® KR2861

- Luran® KR2864

- Luran® KR 2867

Sabic Geloy®

- CR7020

- XP 4025; XP 7560

- XP7550

- HRA 222

PRODUCT Q&As

Q. What kind of material is PC/ASA?

Q. What is PC/ASA used for?

Q. What is the difference between PC/ASA and PC/ABS?

Q. Is ASA better than ABS?

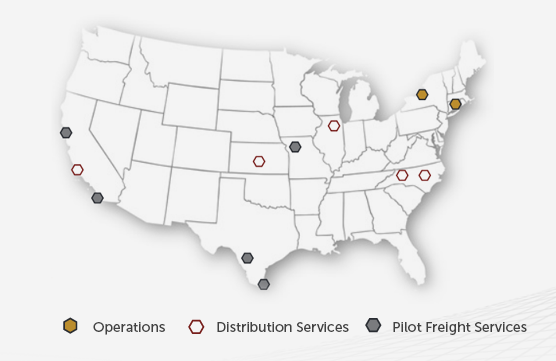

Our Mission

My mission at Polymer Resources has not changed since I founded this company more than four decades ago. It includes continuing our tradition of financial stability, sustainable growth and visionary leadership that compounds success for customers, suppliers and employees. It also means proudly manufacturing our products in America, and making them available to the global marketplace.

Les Klein, Chief Executive Officer, Polymer Resources, Ltd.

Print

Print Download

Download Email

Email