PC/PBT Resin

What is a PC/PBT PLASTIC MATERIAL BLEND?

PC/PBT Resin Plastic Material Blend (polycarbonate / polyester blend) is a thermoplastic alloy of amorphous polycarbonate and semi-crystalline polyester (either polybutylene terephthalate or polyethylene terephthalate). PC/PBT provides a combination of chemical resistance, temperature resistance, and mechanical strength.

Our polymer compounding technology allows us to prepare alloys of Polycarbonate (PC) and Polyesters (either PBT or PET).

PBT Material Properties

Polycarbonate (PC) is used in many applications because PC provides excellent toughness, high rigidity, and good heat resistance. Polycarbonate does have a weakness with resistance to organic chemicals. Polyesters such as PBT plastic and PET have a very high resistance to organic chemicals because they are semi-crystalline. These materials are also rigid and can hold up to high temperatures. The crystallinity of polyesters causes them to have both high specific gravity and high shrinkage values. Polyesters such as PBT and PET also have very low notched Izod impact values.

With our compounding extruders, Polymer Resources can blend PC and either PBT material or PBT into polymer alloys that combine the desirable properties of both PC and the polyester, and that minimize the less desirable properties. These alloys offer the toughness of PC along with the chemical resistance of the polyesters. Chemical resistance can be “fine-tuned” by varying the ratio of PC to polyester. Specific gravity and shrinkage of these alloys are less than that of polyesters and greater than that of PC.

The properties of our PC/PBT alloys can be further enhanced by the addition of additives during compounding. Impact modifiers can be added to provide products with a very good low-temperature impact. Flame retardants can be added to provide products with UL 94 V-0 ratings. Glass fibers can be added to provide products with high flex strength. Stabilizers can be added to improve resistance to UV radiation and to improve thermal stability. Also, colorants can be added in order to provide a specific property profile in any given color.

Additives, Modifiers, and Reinforcing Agents:

- Additives – UV stability, easy release (mold releases), colorants, and other stability additives

- Modifiers – Flame retardants, impact modifiers, flow enhancers

- Reinforcing Agents – Glass fibers, mineral fillers

PRL Alternative Material Solutions to

Example: If you’re looking for Covestro Makrolon alternatives or Sabic Lexan alternatives: find the product in the relevant row and look to the leftmost row to find our alternative.

PRL Grades

- PRL PC/TP GP1

- PRL PC/TP GP2

- PRL PC/TP GP2 G10

- PRL PC/TP GP2 G20

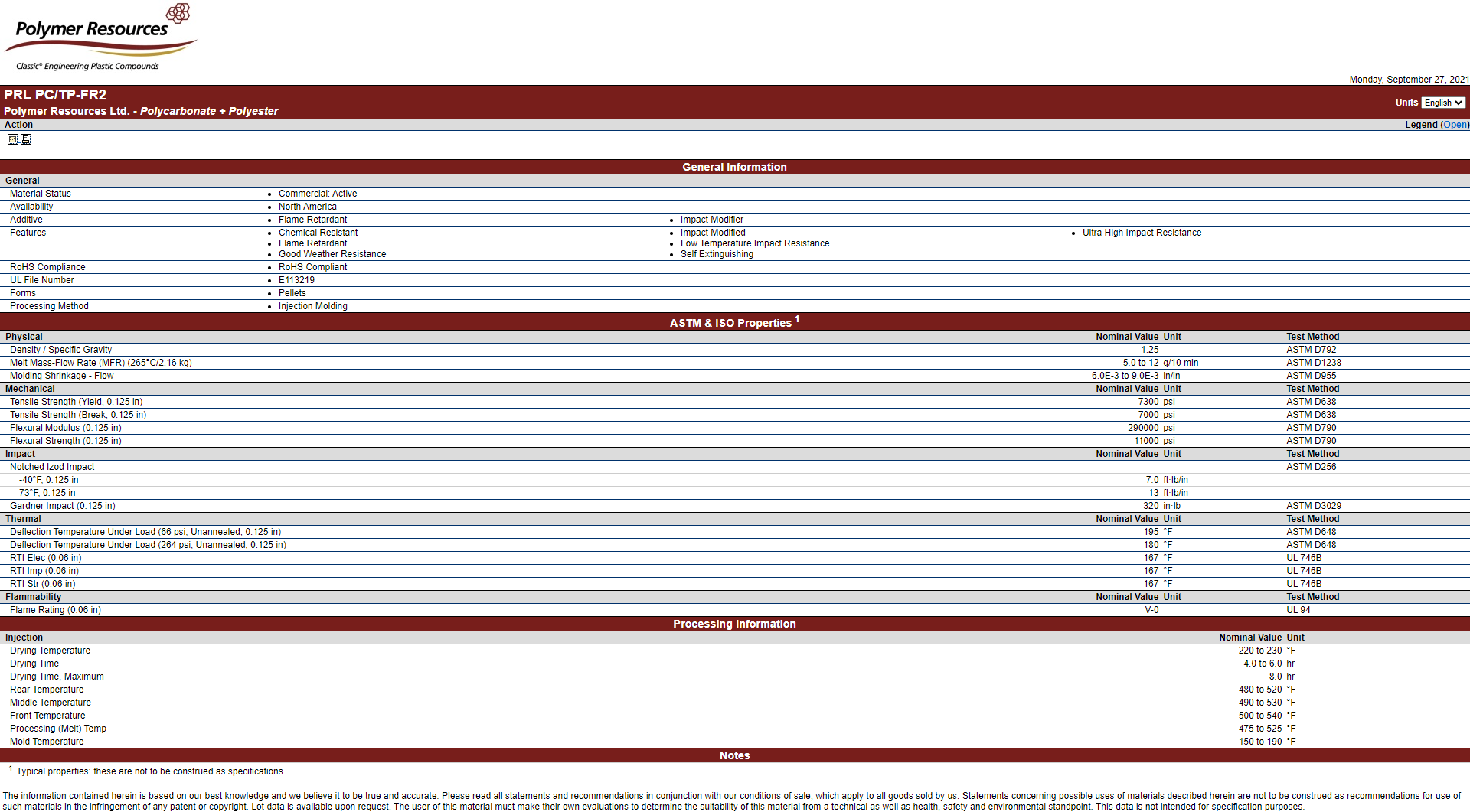

- PRL PC/TP FR2

- PRL PC/TP GP3

- PRL PC/TP GP3 G10

- PRL PC/TP GP3 G30

- PRL PC/TP FR3

Covestro Makrolon®

- UT250, UT400

- UT 1018

- UT 620G

- UT 640G

SABIC Lexan®

- 2230, 2730, 2735

- 1102,1731,1732,5220,5230,5270

- 1760

- 5770

- Valox 364

- 1200, 6123, 6127, 6620

- 6240

- 6370

- Valox 3706

PRODUCT Q&As

Q. What are the benefits of a PC/PBT blend?

Q. What are the disadvantages of a PC/PBT blend?

Q. What is PC/PBT used for?

Q. What is the difference between PBT and PET?

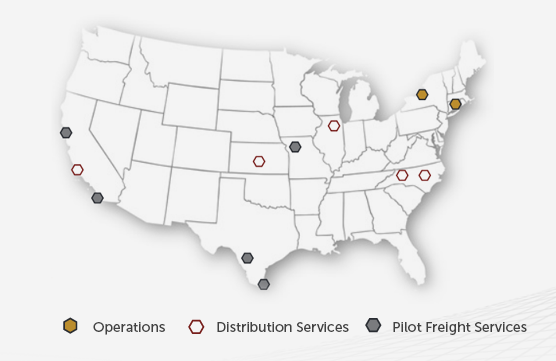

Our Mission

My mission at Polymer Resources has not changed since I founded this company more than four decades ago. It includes continuing our tradition of financial stability, sustainable growth and visionary leadership that compounds success for customers, suppliers and employees. It also means proudly manufacturing our products in America, and making them available to the global marketplace.

Les Klein, Chief Executive Officer, Polymer Resources, Ltd.

Print

Print Download

Download Email

Email