Polycarbonate (PC) Resin

What is Polycarbonate (PC) Resin?

Polycarbonate is an amorphous engineering polymer that provides exceptional mechanical, thermal, and optical properties. Polycarbonate is one of the only plastics that combine thermal stability, high upper use temperatures (HDT), impact resistance and toughness as well as clarity. Polycarbonate exhibits impact resistance and toughness at a wide range of temperatures. It has superior thermal stability, which yields a large process window for large and small parts. Its amorphous nature gives polycarbonate excellent dimensional stability and uniform shrinkage. Polycarbonate is available as a clear material (up to 85% light transmission) and in a wide variety of custom colors that are transparent, translucent, and opaque.

Polycarbonate can be blended with glass fibers, flame retardants, UV stabilizers, and even friction-reducing agents to produce a product line with superior mechanical, impact, and optical properties.

Polycarbonate has been the material of choice in many industries, including industrial and electrical parts, automotive end uses, as well as many different types of lenses.

Additives, Modifiers, and Reinforcing Agents:

- Additives – UV stability, easy release (mold releases), colorants, and other stability additives

- Modifiers – Flame retardants, impact modifiers, flow enhancers

- Reinforcing Agents – Glass fibers, mineral fillers

PRL Alternative Material Solutions to

Example: If you’re looking for Covestro Makrolon alternatives or Sabic Lexan alternatives: find the product in the relevant row and look to the leftmost row to find our alternative.

PRL Grades

- PRL PC-GP1-D

- PRL PC-GP2-D

- PRL PC-GP3-D

- PRL PC-GP4

- PRL PC-UV1-D

- PRL PC-UV2-D

- PRL PC-UV3-D

- PRL PC-UV4

- PRL PC FD1

- PRL PC FD2

- PRL PC FD3

- PRL PC FD4

- PRL PC-FR1-D

- PRL PC-FR2-D

- PRL PC-FR3-D

- PRL PC-FR1A-D

- PRL PC-FR2A-D

- PRL PC-FR3A-D

- PRL PC-IM1

- PRL PC-IM2

- PRL PC-IM3

- PRL PC-IM4

- PRL PCSF-FR

- PRL PCSF-FR1

- PRL PCSF-FRG20

- PRL PCSF-FRG30

- PRL PC-HM-FR1

- PRL PC-HM-FR2

- PRL PC-G10

- PRL PC-G20

- PRL PC-G30

- PRL PC-G40

- PRL PC-BR1

- PRL PC-BR1-UV

- PRL PC FRUV2

- PRL PC HH

- PRL PC FR TFE

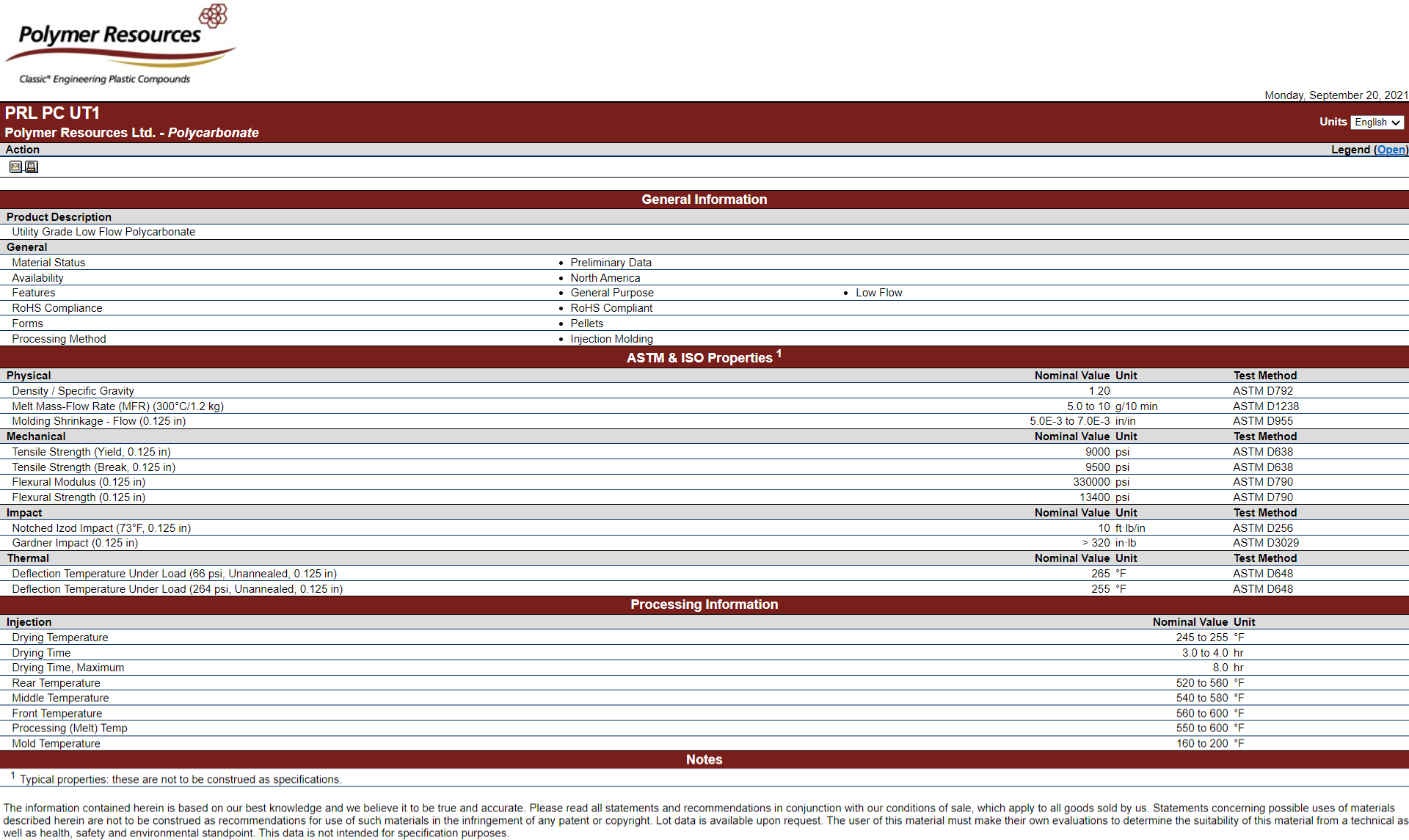

- PRL PC UT1

- PRL PC UT2

- PRL PC UT3

Covestro Makrolon®

- 3105

- 2605, 2805

- 2505

- 2405

- 3103, 3107

- 2607, 2807, AL 2647

- 2507, AL2447

- 2407, AL2247, AL2447

- 3108, 3158

- 2658, 2858

- 2558

- 2458

- 6465, 6485

- 6265

- 6455, 6555

- 6255, 6355

- 1260, 1881

- T7855, 1837

- T7435

- SF800

- SF810

- 9415

- 9415

- 8325, 9425

- 2665

- Apec® 1603

SABIC Lexan®

- 101, 201

- 141, 241

- 121, 221

- HF1110

- 103, 203, LS3

- 143, 243, LS2

- 123, 223, LS1

- HF1130, LSHF

- 104, 204

- 144, 244

- 124, 224

- HF1140

- 950

- 940

- 920

- 950A

- 940A

- 920A

- EM1210, EXL6414

- EXL1414, EXL1434

- EM3110, EXL1112

- FL900, FL1600

- FL410, FL910

- FL920

- FL930

- 500

- 500

- 3412

- 3413

- 3414

- 151

- 153

- 925, 945, 955

- XHT1141

- Lubricomp® DL 4020 FR

- ZLL01CP, PC RC T2

- ZLL12CP, PCRCT

- ZLL19CP, PCRTC

Trinseo Calibre®

- 300-6, 300V-6

- 300-10, 300V-10

- 280-15, 300-15, 300V-15

- 280-25, 300-22, 300V-22

- 302-6, 302V-6

- 302-10, 302V-10

- 302-15, 302V-15

- 302-22, 302V-22

- 200-6, 200V-6

- 200-10, 200V-10

- 200-15, 200V-15

- 200-22, 200V-22

- 890-6

- 890-10

- 890-15, 890-20

- 700-6

- 700-10

- 700-15

- IM 401-11

- IM 401-18

- SF7070

- SF7100

- 7100

- 7100

- 5200, 7200

- 600-2, 600-3

- 602-2, 602-3

PRODUCT Q&As

Q. What are the advantages and disadvantages of polycarbonate?

Q. What are the UV characteristics of polycarbonate?

Q. Does clear polycarbonate turn yellow?

Q. Does polycarbonate absorb water?

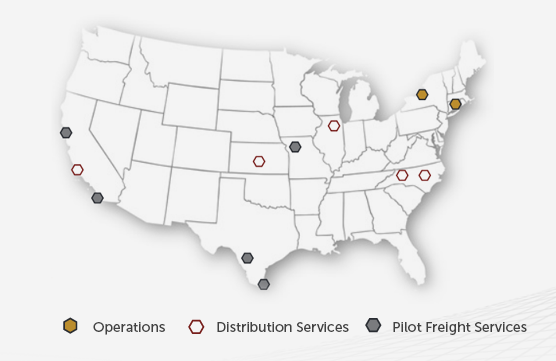

Our Mission

My mission at Polymer Resources has not changed since I founded this company more than four decades ago. It includes continuing our tradition of financial stability, sustainable growth and visionary leadership that compounds success for customers, suppliers and employees. It also means proudly manufacturing our products in America, and making them available to the global marketplace.

Les Klein, Chief Executive Officer, Polymer Resources, Ltd.

Print

Print Download

Download Email

Email