Polyetherimide (PEI) Resin

What is PEI Resin?

Polyetherimide (PEI) resin is an amorphous, amber-to-transparent, high-performance engineered thermoplastic distinguished by its exceptional mechanical and thermal properties. It offers high strength, stiffness, and chemical resistance, maintaining predictable performance even at elevated temperatures up to 200°C, with a glass transition temperature of 217°C (422°F).

This resin exhibits superior dimensional stability and is highly creep resistant, while also possessing inherent flame resistance without the need for additives.

In terms of manufacturing, it offers good processability and can be readily extruded, thermoformed, or injection molded. Uniquely among engineering plastics, PEI exhibits one of the highest dielectric strengths—around 25 kV/mm at 1.6 mm thickness—which makes it ideal for electrical insulators, capacitor housings, and high-voltage connectors.

Consequently, its balance of cost and high performance secures its usage in critical high-value applications within the electronics, healthcare, automotive, and aviation industries where strength, insulation, and thermal endurance are essential.

Additives, Modifiers, and Reinforcing Agents:

- Additives – UV stability, easy release (mold releases), colorants, and other stability additives

- Modifiers – Flame retardants, impact modifiers, flow enhancers

- Reinforcing Agents – Glass fibers

PRL Alternative Material Solutions to

Example: If you’re looking for Sabic Ultem alternatives: find the product in the relevant row and look to the leftmost row to find our alternative.

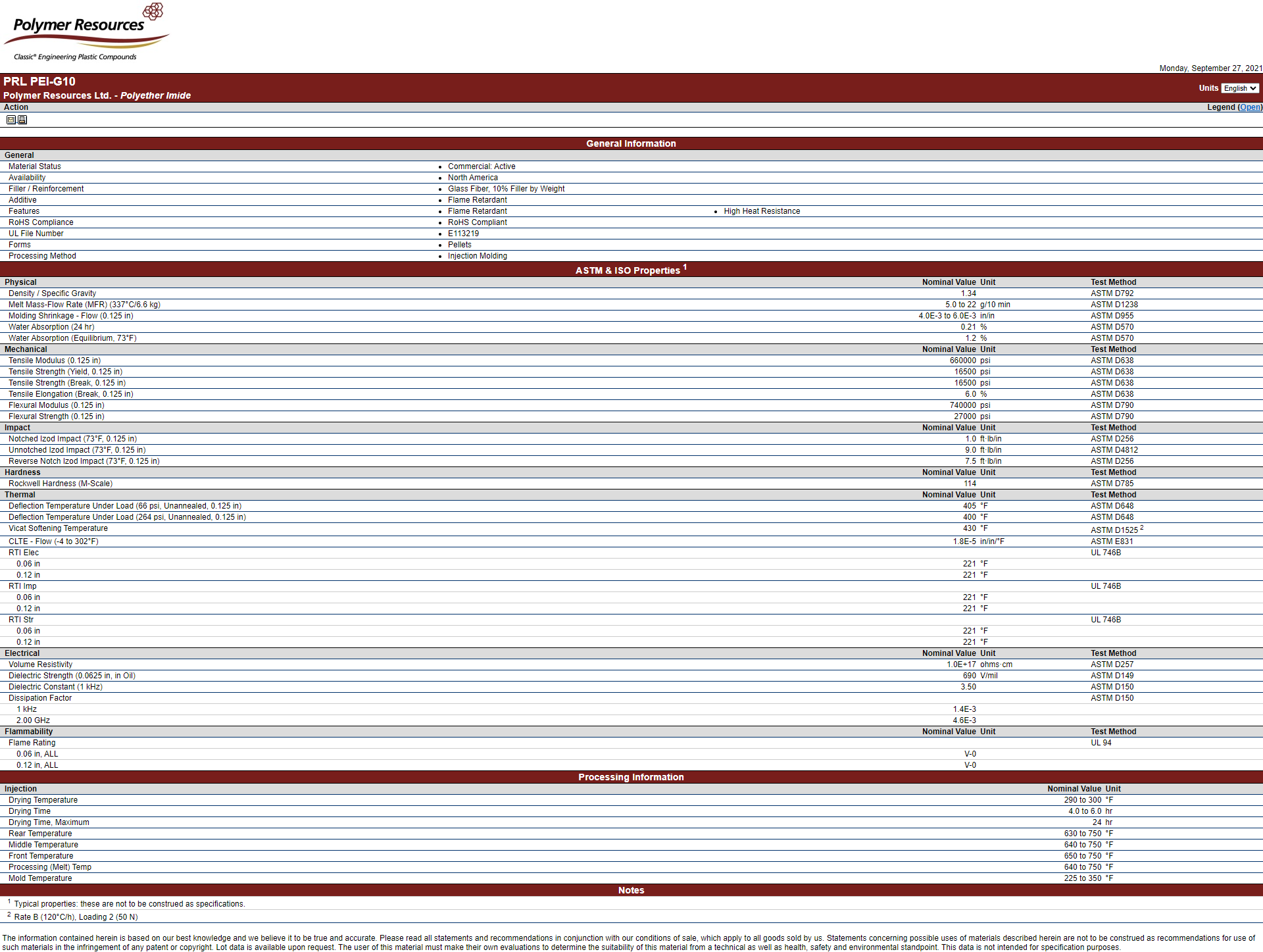

PRL Grades

- PRL PEI-GP1

- PRL PEI-G10

- PRL PEI-G20

- PRL PEI-G30

- PRL PEI-G40

Sabic Ultem®

- 1000,1010

- 2100, 2110

- 2200, 2210

- 2300, 2310

- 2400, 2410

PRODUCT Q&As

Q. What is the development history of PEI?

Q. What are the advantages and disadvantages of PEI?

Q. What applications is PEI used for?

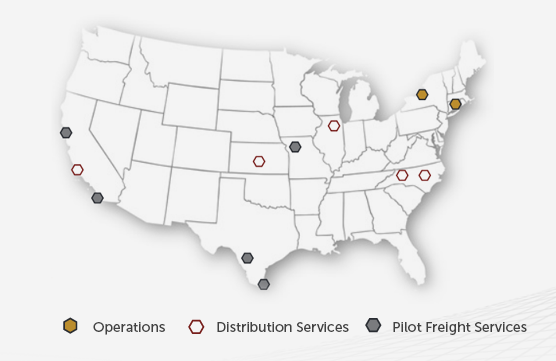

Our Mission

My mission at Polymer Resources has not changed since I founded this company more than four decades ago. It includes continuing our tradition of financial stability, sustainable growth and visionary leadership that compounds success for customers, suppliers and employees. It also means proudly manufacturing our products in America, and making them available to the global marketplace.

Les Klein, Chief Executive Officer, Polymer Resources, Ltd.

Print

Print Download

Download Email

Email