by Todd Hotes | Sep 14, 2024 | Blog

Choosing the right resin is essential because different resins affect a product’s performance, durability, and longevity.

In this blog, we’re focusing on three primary resins: Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), and Acrylonitrile Styrene Acrylate (ASA).

Each of these resins offers unique properties with their own pros and cons. Choosing the wrong resin can lead to issues such as poor weather resistance, decreased longevity, and even total failure. That’s why it’s important to understand the distinct advantages and limitations of each resin so you can make an informed decision. Ultimately, choosing the right resin can save you time and money in the long run.

(more…)

by Todd Hotes | May 10, 2024 | Blog

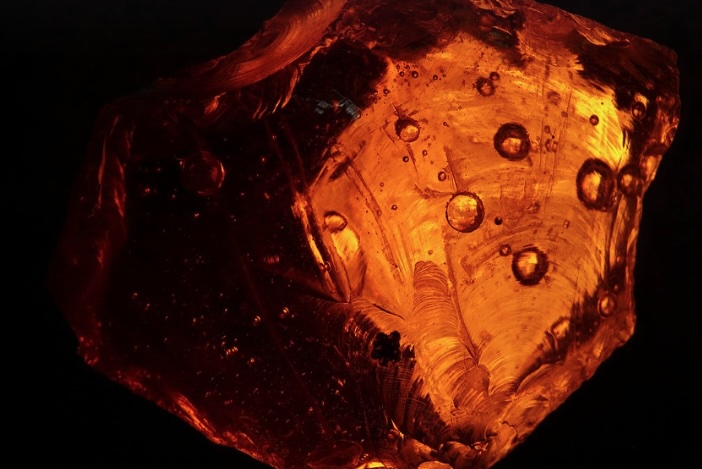

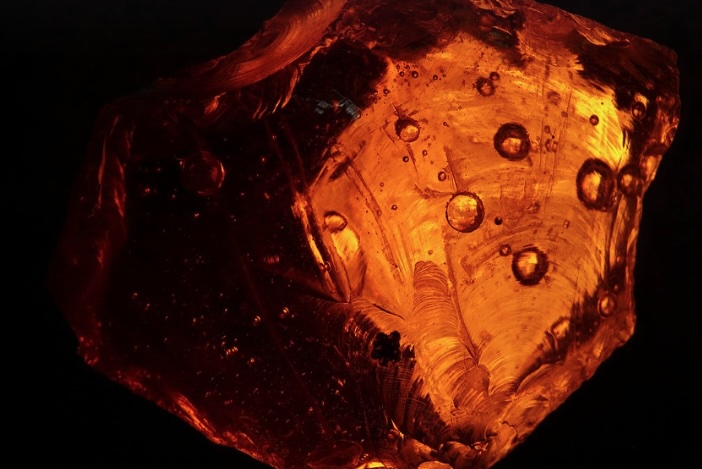

There are two main types of resins: natural and synthetic. Both types of resins have a rich history. And while we focus on Polymer Resins here, we do feel it’s important to educate across both types so that we all better grasp the concepts from a general perspective.

Let’s begin with a little history lesson.

(more…)

by Todd Hotes | Nov 10, 2023 | Blog

The world of engineering thermoplastics continues to “charge” forward within the electric vehicle(EV) revolution. Vehicles, either partially or entirely powered by electricity, are leveraging the power of engineering thermoplastics throughout their manufacturing processes. From battery enclosures to a variety of structural components, engineering thermoplastics are making a significant difference in EV production.

Let’s break down how engineering thermoplastics play a powerful role in EV products and what the future may hold.

(more…)

by Todd Hotes | Oct 29, 2023 | Blog

One of polymer resins’ strongest suits undoubtedly lies in it’s ability to help products endure the elements. This can add years to a product’s lifecycle which ultimately helps sell more products to consumers. Product manufacturers heavily focus on weather resistance for this exact reason. Outdoor applications are as popular as ever, particularly in the technology realm; thus, weather-resistant materials such as ASA are a core component.

Let’s explore how ASA helps bring longer life to a myriad of our everyday outdoor applications.

(more…)

by Todd Hotes | Sep 18, 2023 | Blog

In healthcare, the materials used serve as a vital influence on the quality of care for patients and the costs they pay. Modern medical device manufacturing advancements hinge primarily on the revolution of polymer resins.

Polymer resins are a class of synthetic organic compounds. In manufacturing, it’s polymer resins adaptability for complex shaping that makes them a viable component. As polymer science evolves, the medical industry is increasingly leveraging its power.

Let’s dive deeper into the role of polymer resins in the medical field.

(more…)

by Todd Hotes | Aug 27, 2023 | Blog

The evolution of construction has an obvious, and essential, relationship with the materials it uses. Throughout history, available materials have shaped the way construction has progressed. From the mud bricks of ancient Mesopotamia to the steel beams of modern skyscrapers, we see it everywhere around us, all throughout history.

Today, we aren’t using mud bricks. Instead, materials such as polymer resins are emerging as materials used to create rigorously strong, safe, and cost-effective construction.

From the durability of Polycarbonate (PC) to the versatility of Acrylonitrile Butadiene Styrene (ABS), polymers offer benefits that many legacy materials can’t compete with.

From the inception of a working construction project to the final touches, we’ll explore how essential polymer resins help us build for a better future.

(more…)