Makrolon vs. LEXAN: Finding the Right Polycarbonate Alternative

When you are choosing a material for tough, high-impact applications, polycarbonate is often at the top of the list.

It is strong, lightweight, and versatile, making it a go-to option in industries ranging from medical devices to construction.

Two of the biggest brand names in polycarbonate are Makrolon and LEXAN. Both are well known, and both have built solid reputations for performance. But they’re not the only choices out there.

At Polymer Resources, we offer reliable, U.S.-based polycarbonate options that deliver the same impact strength and durability without the supply chain headaches or premium price tag that can come with major brands.

What is Polycarbonate?

Polycarbonate is a type of plastic that stands out because it’s tough yet lightweight. Imagine something as clear as glass, but far more durable; that’s polycarbonate. It can handle strong impacts without breaking, which makes it useful in all kinds of industries.

You’ll find polycarbonate in everyday items like safety glasses, medical devices, building materials, and even electrical components. Its ability to resist impact, stay clear, and handle heat makes it a favorite when strength and safety matter most.

Both Makrolon and LEXAN are simply brand names of this versatile material. Let’s explore this extraordinary material in more detail.

Makrolon and LEXAN: The Big Names

When people talk about polycarbonate, two names often come up first: Makrolon and LEXAN.

And that’s fair.

These brands have been around for decades and have earned a strong reputation in industries where performance can’t be compromised.

- Makrolon is widely recognized for its durability and excellent optical clarity, making it a popular choice for applications where visibility and strength go hand in hand.

- LEXAN is known for its toughness and versatility. It’s often used in demanding environments where impact resistance and reliability are essential.

Even though they come from different manufacturers, both Makrolon and LEXAN are simply variations of the same material: polycarbonate. Their popularity comes down to trusted performance, wide availability, and long histories in the marketplace.

In other words, they’re both outstanding options.

Key Differences Between Makrolon and LEXAN

While both Makrolon and LEXAN are polycarbonate, there are a few subtle differences worth noting:

- Impact Strength: Both are highly impact-resistant, though certain Makrolon grades are often highlighted for extra toughness.

- Optical Clarity: Makrolon is commonly chosen for applications needing clear, glass-like transparency, while LEXAN is more widely used where clarity isn’t the top priority. Source > Covestro AG

- Heat Resistance: Performance is similar, though grade variations can shift the balance slightly depending on application. Source > Covestro AG

- Cost & Availability: Prices can fluctuate between the two brands, and availability may depend on regional supply chains.

In practice, the differences aren’t dramatic, both materials are trusted for high-impact, high-performance applications.

Why Consider Alternatives?

Makrolon and LEXAN have strong reputations, but relying only on big-name brands can sometimes come with challenges.

Prices may swing depending on global supply and demand, and long lead times can slow down projects. For manufacturers working on tight schedules and budgets, that can create real headaches.

Another challenge with global suppliers can be high minimum order quantities. For example, customers buying LEXAN from SABIC may face large MOQs or be pushed toward premium, higher-cost grades just to secure smaller lots.

That’s where alternatives come in. Choosing a reliable, domestic supplier gives you more control. You can count on consistent availability, avoid supply chain bottlenecks, and often save on costs without sacrificing performance.

At the end of the day, what matters most is getting material that performs the way you need it to without the added stress of unpredictable pricing or delayed shipments.

Polymer Resources’ Polycarbonate Solutions

At Polymer Resources, we understand that manufacturers need more than just a material, they need a partner they can rely on.

That’s why our polycarbonate resins are designed to deliver the same high-impact performance you’d expect from Makrolon or LEXAN, but with the added benefits of a domestic, dependable supply chain.

Here’s what sets us apart:

- Consistent Availability – U.S.-based supply means shorter lead times and fewer disruptions.

- Custom Formulations – Tailored solutions for unique applications, plus full color matching capabilities.

- Minimum Order Quantity – Smaller custom compounded lots as low as 250lb (with fully compounded color)

- High-Impact Performance – Toughness and durability on par with the big brands.

- Cost-Effective – Competitive pricing without sacrificing quality.

- Technical Support – Our experts help guide material selection and processing so you get the best fit every time.

With Polymer Resources, you get the performance your application demands and the reliability your business depends on.

FAQ: Polycarbonate Choices for High-Impact Applications

Are Makrolon and LEXAN different materials?

No, both are brand names for polycarbonate. While each brand has its own product grades and strengths, they’re both built on the same tough, impact-resistant plastic.

Why would a company consider alternatives to Makrolon or LEXAN?

Executives often look for alternatives when facing supply chain delays, cost fluctuations, flexible order quantities, or limited availability. A domestic supplier like Polymer Resources helps reduce risk while maintaining performance standards.

Can Polymer Resources’ polycarbonate really match the performance of big-name brands?

Yes. PRL’s polycarbonate resins are designed for the same impact strength, durability, and versatility as leading brands, with the added advantage of local support and consistent supply.

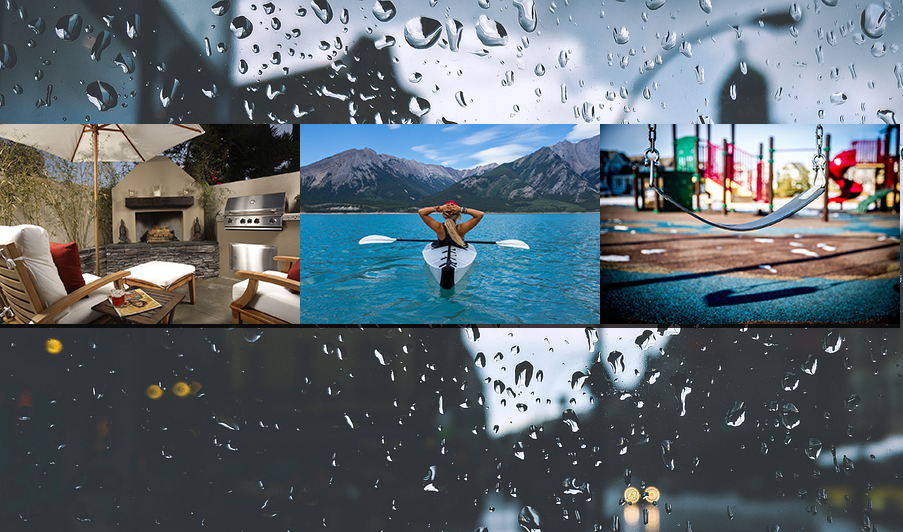

What industries benefit most from PRL’s polycarbonate solutions?

We serve industries where safety, reliability, and performance are critical: medical devices, building & construction, electrical, and consumer goods.

How does PRL support companies beyond just supplying material?

Polymer Resources goes beyond selling resin by offering custom formulations, color matching, regulatory compliance expertise, flexible order quantities, and technical consulting, helping businesses find the right fit for their exact application.

What’s the biggest advantage for executives choosing PRL over global brands?

It comes down to control and reliability. By working with a U.S.-based supplier, companies avoid costly delays, stabilize budgets, and gain a partner who can adapt solutions to their needs.