UL Listings

UL 94 Listings

UL 94 is the flammability standard which determines a material’s likelihood to either spread or put out a flame once the material has been lit on fire. The UL 94 testing can present a variety of determinations including hourly fire resistance ratings, surface burning characteristics, roof covering flammability ratings and flammability of contents within a structure. The testing is done on a small scale to evaluate the flammability of the plastic used in various parts under controlled conditions. There are three types of UL 94 ratings we typically use:

HB Rating

- Samples are place horizontally and ignited

- The flame must burn slowly across the sample V (V-0, V-1, or V-2) Rating

- Samples are placed vertically and ignited

- The flame must extinguish within specific time frames and not drip material

5V (5VA or 5VB) Rating

- Samples tested both vertically and horizontally

- The flame must burn slowly across the sample V (V-0, V-1, or V-2) Rating

- Samples are placed vertically and ignited

- Five applications, 5 seconds on, 5 seconds off

UL 746B Listings

UL 746B is the standard for long term property evaluations which determines a material’s thermal aging. This test is used to determine the ability for the tested material to retain its properties after extensive exposure to high temperatures. UL 746B includes a variety of components including dielectric, tensile and impact testing. The RTI or relative temperature index is assigned beforehand, based on the material’s specific application. The RTI comparison from before the testing and after is used to determine thermal aging over a period.

There a several types of RTIs given based upon the material application:

- Electrical RTI

- Mechanical Impact RTI

- RTI Elongation

- Mechanical Strength RTI

UL 746C Listings

UL 746C is the standard for UV and water testing. This type of testing is suitable for materials that are meant to be used in an outdoor application. To test UV, the material is either put into a twin-enclosed carbon weatherometer for 720 hours, or a xenon-arc weatherometer for 1000 hours. To test whether the material can withstand water exposure, it is immersed into water for 7 days at 70°C. There are two types of UL 746C Ratings:

F1 Rating

- The material has passed both the water and UV testing.

F2 Rating

- The material has passed either the Water or UV testing but not both

- The material has only been partially tested

About Polymer Resources

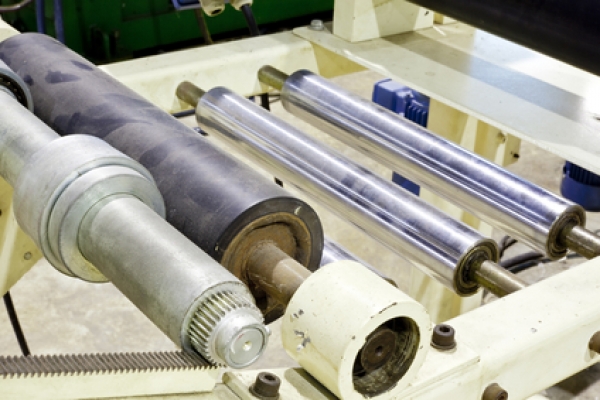

Headquartered in Farmington, Conn., Polymer Resources is a leading, privately owned U.S. supplier of high-quality customized specialty engineering resin compounds, color-matching services and related materials technology solutions for the electrical, medical, consumer goods, business equipment and automotive industries. Operating with an extensive list of UL approved products, it is one of very few polymer suppliers that backs its compounding and color match services with a quality guarantee. The company’s commitment to customer service, financial discipline, and foresight for over 45 years has made it a reliably steady resource for specialty compounds in the often-volatile plastics industry. With operations in Farmington and Rochester, N.Y., Polymer Resources continues to fuel its growth through ongoing investments in its manufacturing assets and its top industry talent. The company’s direct sales force and local warehousing throughout the United States enable on-time delivery and fast, local customer service anywhere in the country.

For more information, visit www.prlresins.com