In a variety of manufacturing and industrial processes, there’s a need for polyurethane resin impregnation – an easy process of filling porous material using polyurethane resins, as well as making it impervious. The process assists in addressing issues associated with micro porosity in powder-metal parts, metal castings, plastic composites, electronic components, welds, and additional porous substrates – if gone untreated, it might result in poor quality of surface finish and pressure leakage. It brings an immediate necessity of an in-demand resin impregnation technology which will treat any kind of porous issues and improves their potential, while simultaneously ensuring performance that is free of leaks.

Before exploring any further, let us understand more on Polyurethane Resin Impregnation technology. It’s amongst the most typical methods utilized to seal the voids and cavities between the wire windings, which result in improved electrical insulation. Also, the impregnation assists in decreasing vibrations by repairing the wires surroundings the windings. In plain terms, it’s a standard method of avoiding component leakage, and upgrading the surface treatment.

Polyurethane (PU and PUR) polymers, in this approach, are utilized as resin blend in order to seal open pores. There isn’t any secret that it’s a ‘resin of choice’ as it will come to surface coatings, electrical potting compounds, high performance adhesives, and surface sealants. They’re valued for their resin properties. Pressure, vacuum, and temperature include the main parameters utilized in Polyurethane impregnation processing. Make sure you provide maximum attention to the correct viscosity; otherwise incorrect viscosity might lead to stress cracks and incomplete saturation.

Polyurethane impregnation approach possesses numerous benefits. Let us examine look some major advantages of the same:

- Boost in thermal conductivity

- Better electrical insulation with minimal vibrations

- No resin residuals on laminations and shafts

- High bond strength

- Develops a bonding effect upon the lamination

- No presence of bubbles within the resin-winding mass

- Accurate penetration of resin deep inside a variety of existing gaps

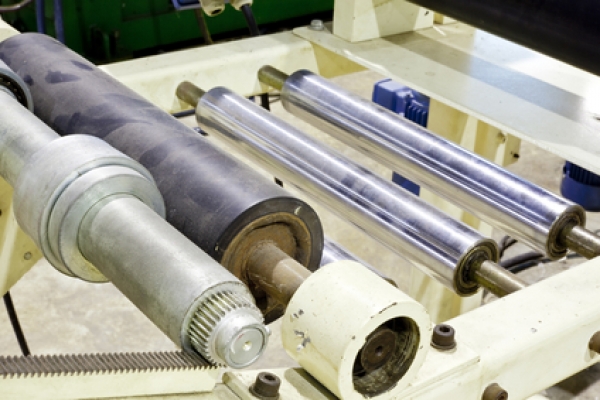

The most broadly utilized equipment for Polyurethane Resin Impregnation include vacuum potting, Hot Dipping, Roll Dip, and Trickling. You easily can discover numerous available choices in the marketplace for them. But, what’s important is that you select the proper machine from the proper dealer.

While planning to purchase an impregnation machine, you ought to provide utmost importance to factors such as yield of resin, energy optimization, programmable auto shut down and start, automatic flushing of drippers and pumps, automatic system lubrication, automatic failure diagnostics, ease of operation, low maintenance, low thermal dissipation, and much more. Do not forget to check the manufacturer’s warranty, specifications, and quality prior to making a final purchase.

For more information on this process contact Polymer Resources at 1-860-271-0497.